-

FASHIONHOT TRENDSJEANCI CLOTHING INDUSTRY

FASHIONHOT TRENDSJEANCI CLOTHING INDUSTRY -

DESIGN / DEVELOP / PRODUCEWe develop our designs through the expositions we have participated

DESIGN / DEVELOP / PRODUCEWe develop our designs through the expositions we have participated

as participant and visitor, with our design team and our experience

in the fashion sector at our R&D centers in Serbia and Turkey.We

complete the ‘DDP’ process during the production of the collections

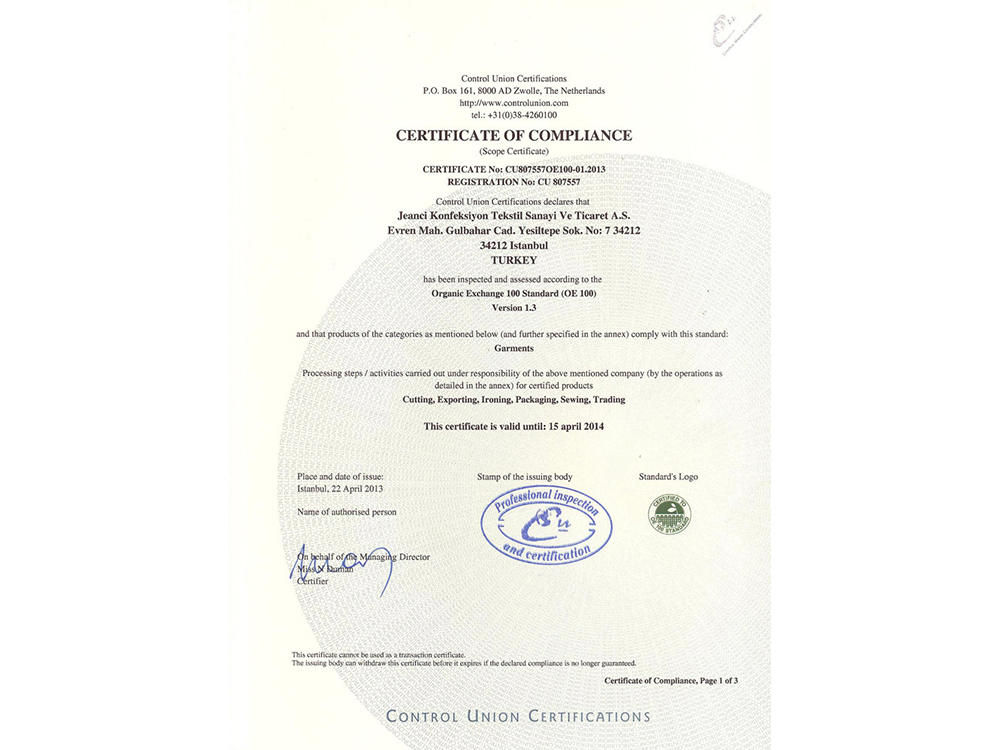

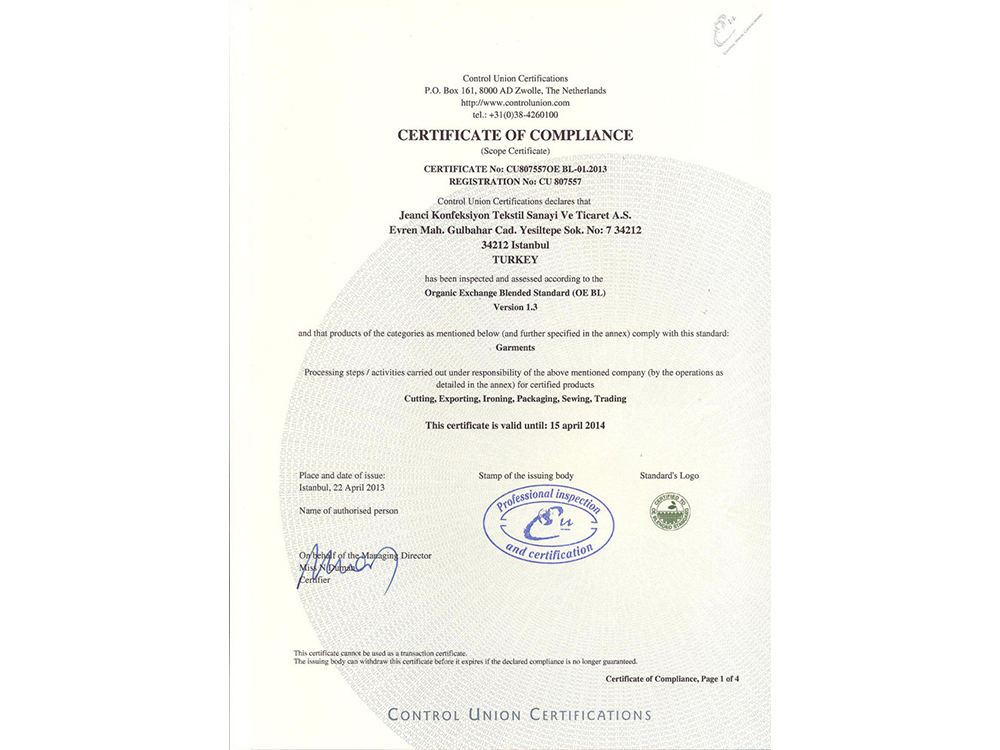

we offer you by remaining faithful to environment friendly, sustainable

and innovative policies.